Spindle Moulders

A spindle moulder is your trusty partner in the art of woodworking, bringing your most creative designs to life. This machine, equipped with a variety of spindle moulder cutters, is all about versatility and precision. Picture it as a sculptor's chisel, but for wood. It transforms plain pieces into elegantly shaped mouldings, frames, and panels with ease. The heart of a spindle moulder machine lies in its vertical spindle – a powerhouse that spins the cutters to carve wood into beautiful patterns. Whether you're a seasoned professional or a passionate hobbyist, this tool is a game-changer. It's not just about the cuts it makes; it's about the stories those cuts tell in your projects. Safety features ensure your focus stays on creativity, not caution. With a spindle moulder, you're not just working on wood, you're crafting legacies in every grain.

What you need to know before you buy a spindle moulder?

When selecting a spindle moulder, a specialised woodworking machine designed for shaping and profiling wood, it's important to choose one that aligns with the specific requirements of your woodworking projects. Spindle moulders are a favourite in both professional carpentry and joinery workshops for their versatility and ability to produce detailed and complex mouldings, rebates, and grooves.

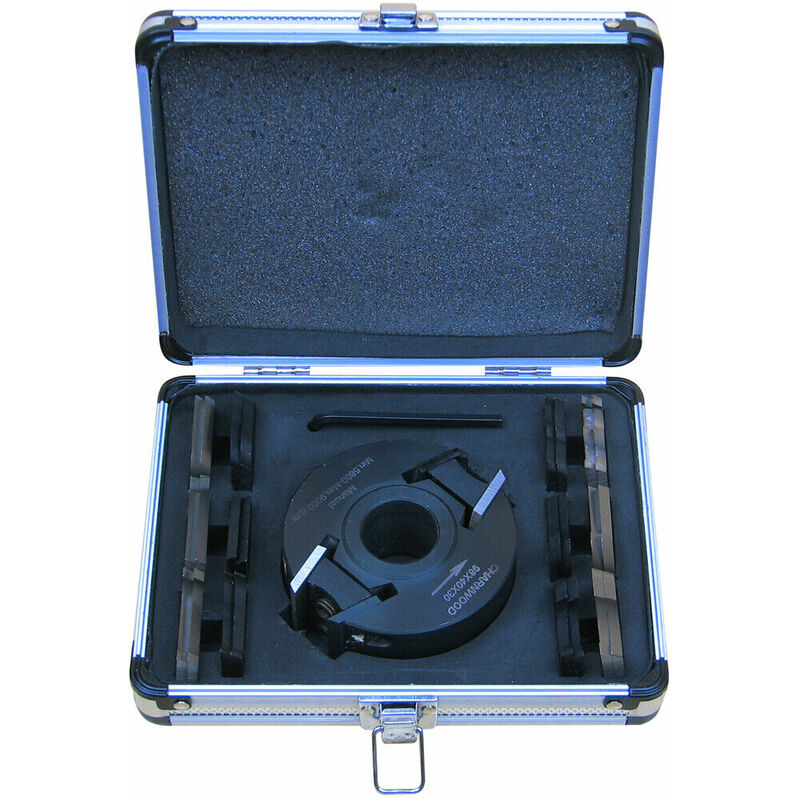

Spindle moulder cutters are key components of the machine, determining the types of shapes and profiles that can be achieved. It's important to select high-quality cutters that are suited to the wood you are working with and the specific profiles you intend to create.

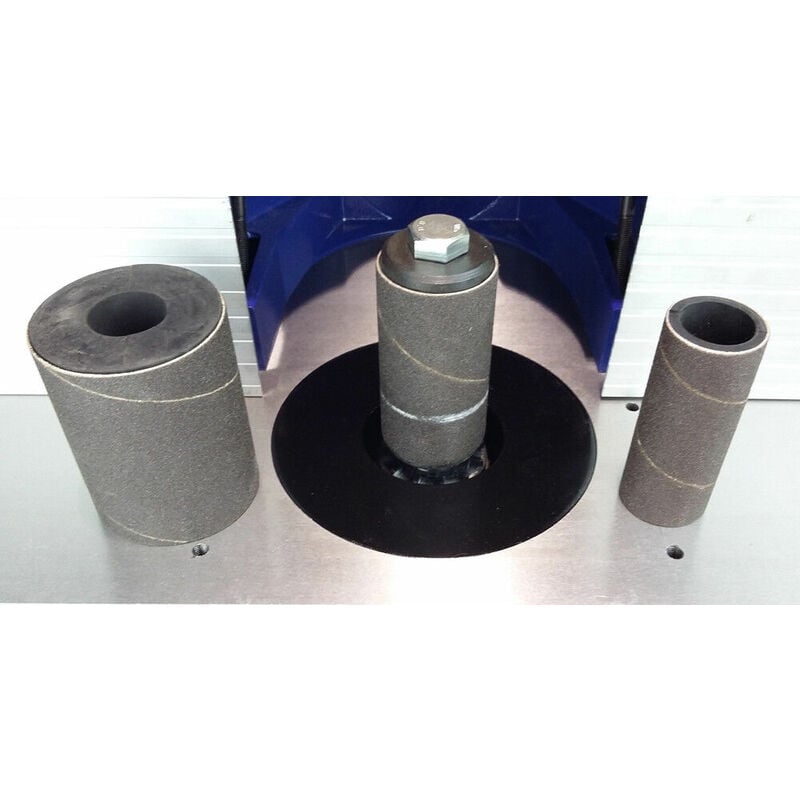

When considering a spindle moulder machine, factors such as the power of the motor, the size of the table, and the range of adjustments for the spindle (including height and angle) are crucial. A more powerful motor can handle harder woods and more demanding tasks, while a larger table provides greater support for bigger workpieces.

Additionally, the safety features of the spindle moulder are paramount. Look for machines with robust guarding systems, emergency stop mechanisms, and options for dust extraction to ensure a safe working environment.

In summary, selecting a spindle moulder involves considering aspects like the power and size of the machine, the range and quality of spindle moulder cutters, and the safety features. Whether for intricate decorative work, joinery, or general woodworking, a spindle moulder provides a specialised solution for shaping wood, enabling the creation of complex profiles and finishes in woodworking projects.