Morticers

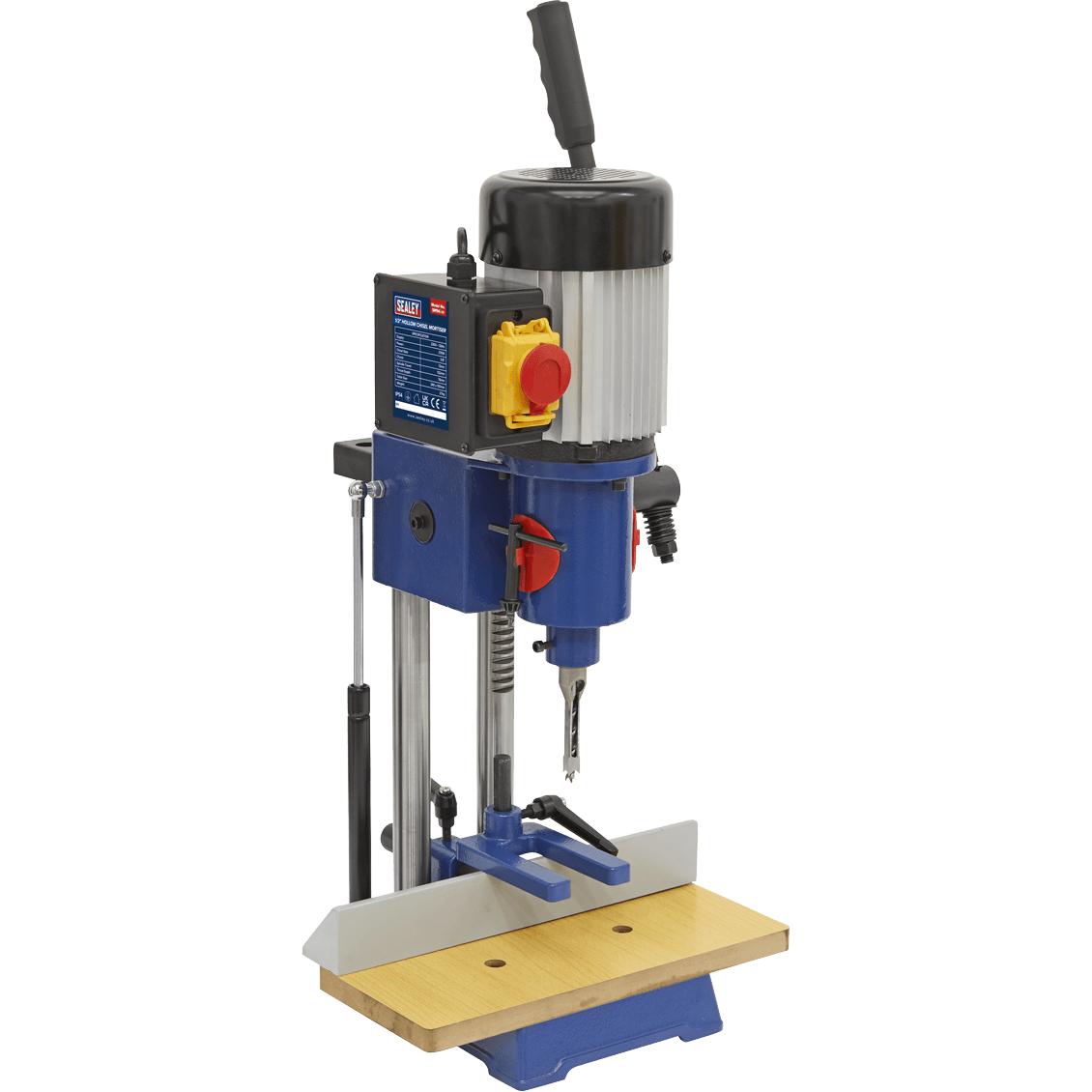

Morticers, an essential tool in woodworking, offer precision and strength for crafting joints. A morticer machine, specifically designed for cutting square or rectangular holes, stands out in its efficiency and accuracy. Ideal for both tradespeople and home enthusiasts, this equipment enhances project outcomes. The bench morticer variant, compact yet robust, easily integrates into any workspace. Its notable feature is the ability to easily position large workpieces, making complex tasks simpler. This machine's versatility caters to a range of applications, from creating intricate furniture joints to robust framework connections. With a morticer, the quality of joinery elevates, ensuring durable and aesthetically pleasing results. Its user-friendly design, combined with powerful performance, makes it a valuable addition to any tool collection. Whether crafting a unique piece of furniture or undertaking a large-scale construction project, a morticer simplifies the process, delivering exceptional precision and reliability.

What to consider before you buy a morticer?

When choosing a morticer, a vital power tool for creating precise joinery in woodworking, it's important to evaluate its features and capabilities to suit your specific needs. A morticer, also known as a mortising machine, is used to cut square or rectangular holes, typically for mortise and tenon joints, a fundamental aspect of furniture making and carpentry.

Deciding between a bench morticer and a more substantial morticer machine depends largely on the scale and frequency of your projects. Bench morticers are more compact, making them suitable for smaller workshops or occasional use. They are great for hobbyists or professionals who need a space-efficient solution. On the other hand, larger morticer machines are designed for more frequent and heavy-duty use, often found in professional woodworking environments.

Power is a key factor in choosing a morticer. More powerful machines can handle tougher woods and larger projects with ease, ensuring smooth operation and consistent results. It's also crucial to consider the machine's capacity, specifically the maximum chisel size it can accommodate, as this affects the range and size of mortises you can create.

Ease of use is another consideration. Features like depth stops, adjustable fences, and easy chisel changes can greatly enhance the user experience. Safety features are also paramount in any power tool, and morticers are no exception. Look for machines with safety guards and emergency stop functions to ensure a safe working environment.

In summary, selecting the right morticer, be it a bench morticer for smaller tasks or a more powerful morticer machine for larger, more frequent use, requires consideration of the tool's power, capacity, ease of use, and safety features. This ensures that the morticer not only fits the specific requirements of your woodworking projects but also provides a safe and efficient working experience.