Air Hammers

Air hammers, a versatile tool in the world of power equipment, redefine efficiency with their robust functionality. These tools harness compressed air to deliver high-impact force, making them ideal for a variety of demanding tasks. A key feature of an air hammer is its ability to work with different attachments, like air hammer chisels, enhancing its utility in sculpting, chipping, and cutting through materials with precision. Typically, heavy-duty air hammers offer greater power and durability, suited for intensive professional use. They are designed to tackle tougher materials and prolonged usage without faltering. In contrast, standard air hammers cater to general-purpose tasks and are often preferred for their lighter weight and ease of handling. The pneumatic air hammer stands out for its efficiency and reliability. It operates using air pressure, which translates into a consistent and powerful performance. This feature makes it a go-to choice for projects requiring steady, repetitive actions. Its ergonomic design often includes features that reduce fatigue, allowing for longer work sessions with increased comfort. Air hammers are not just powerful but also remarkably versatile. They can be used in automotive work, metal fabrication, construction, and even artistic endeavours. Each model offers unique features tailored to specific needs, ensuring that there is an air hammer suited for every task.

What you need to know before you buy an air hammer?

When selecting an air hammer, a specialised tool known for its powerful impact in cutting, shaping, and breaking applications, it’s crucial to choose one that aligns with your specific project requirements. Air hammers are a favourite in automotive work, construction, and metal fabrication for their efficiency in handling tough materials.

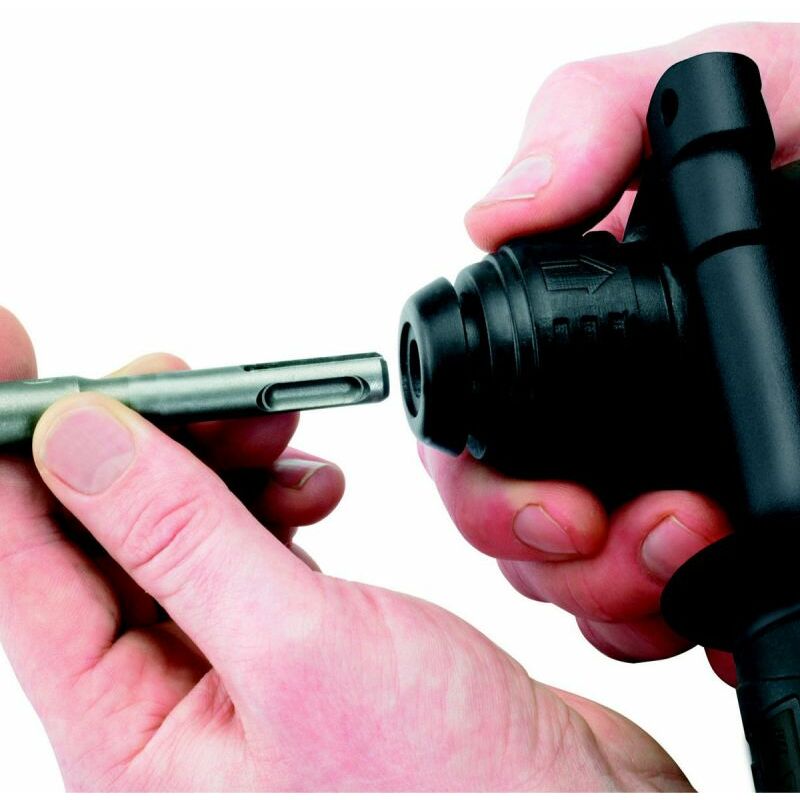

An air hammer chisel is a common attachment for an air hammer, greatly enhancing its versatility. These chisels are used for various tasks such as cutting through metal, breaking up concrete, and removing rust or paint. The variety of chisel tips available allows for a wide range of applications, making the air hammer a highly adaptable tool.

Comparing an air hammer to an air drill, it's important to note their distinct functions. While an air drill is used primarily for drilling holes in various materials, an air hammer is designed for more forceful impact tasks. This distinction highlights the diversity of air tools and their specific uses in different professional and DIY contexts.

When choosing an air hammer, consider factors such as the tool's impact force, the range of chisel attachments available, and the ergonomics of the design. The tool's compatibility with your air compressor (air pressure and flow requirements) is also crucial for optimal performance.

In summary, selecting an air hammer involves evaluating factors like impact power, versatility with different chisel attachments, and ergonomic design. Whether for automotive, construction, or metalwork, an air hammer offers a powerful and efficient solution for a variety of heavy-duty tasks, distinct in function and application from other air tools like air drills.